Foam Conversion: Transforming Foam for Diverse Applications

Foam Conversion is the process of transforming foam materials into various products tailored to meet specific needs across different industries. This conversion can take many forms, ranging from simply cutting foam sheets to creating complex acoustic solutions using advanced machinery. The versatility of foam, including types like polyurethane, polystyrene, and polyethylene, makes it an ideal material for applications in automotive, construction, medical, and more. This article will delve into the intricacies of foam conversion, highlighting its processes, benefits, and applications, ensuring a comprehensive understanding of this essential industry practice.

Understanding Foam Conversion

Foam conversion refers to the various techniques used to manipulate foam into the desired shapes, sizes, and functionalities. This process is essential in creating products that serve specific purposes, from sound insulation to cushioning and packaging. The methods used in foam conversion can be broadly categorized into several key processes:

Types of Foam

- Polyurethane Foam

Widely used for cushions, mattresses, and insulation, polyurethane foam is known for its comfort and versatility. - Polystyrene Foam

Recognized for its lightweight and insulating properties, polystyrene foam is commonly used in packaging, disposable food containers, and thermal insulation. - Polyethylene Foam

Durable and moisture-resistant, polyethylene foam is often utilized in packaging and as padding for various applications.

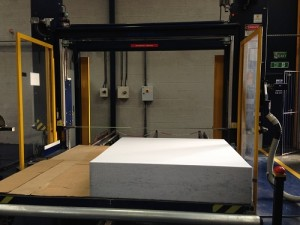

Foam Conversion Processes

Foam can be shaped and altered through various methods, which include:

- Cutting

Foam can be sliced into specific shapes using techniques such as hot wire cutting, water jet cutting, or die cutting. - Moulding

Injection or compression moulding allows foam to be formed into particular shapes and sizes. - Laminating

This process involves bonding multiple layers of foam or adhering foam to other materials to enhance properties. - Fabrication

Finished products are created by assembling foam with other materials.

Applications of Foam Conversion

The applications of foam conversion are vast and span multiple industries. Here are some key areas where foam conversion plays a crucial role:

1. Packaging Solutions

Foam conversion enables the creation of custom packaging solutions designed to protect fragile items during transportation. Tailored foam inserts can be developed to securely hold products, minimizing the risk of damage.

2. Seating and Cushions

In the furniture and automotive sectors, foam is cut and shaped to create comfortable seating and cushions. The flexibility of foam allows for the production of ergonomic designs that enhance user comfort.

3. Insulation

Foam is widely used in construction for thermal and sound insulation. Its lightweight yet effective properties make it ideal for minimizing heat loss and reducing noise transmission in buildings.

4. Medical Products

The medical industry benefits significantly from foam conversion, producing products like medical cushions and orthopedic supports that provide comfort and support to patients.

5. Automotive Components

Foam conversion is vital in the automotive sector, where it is used to create headrests, armrests, and other interior components. These foam products contribute to noise reduction and enhance passenger comfort.

Customization Through Foam Conversion

One of the most significant advantages of foam conversion is the ability to customize products according to specific design, size, and functionality requirements. This level of customization allows manufacturers to cater to unique client needs, ensuring that the final products meet the intended application standards.

Environmentally Friendly Options

In response to increasing environmental concerns, many foam conversion processes now utilize eco-friendly or recycled materials. This initiative helps reduce the overall environmental impact of foam products while maintaining quality and functionality.

Quality Control in Foam Conversion

To ensure that foam products meet industry standards and customer specifications, rigorous quality control measures are implemented throughout the foam conversion process. This commitment to quality is essential for maintaining trust and satisfaction among clients across various sectors.

Industry Expertise in Foam Conversion

Companies specializing in foam conversion often possess extensive knowledge and experience with different foam materials. This expertise allows them to provide tailored solutions for a wide range of applications, ensuring that clients receive the best possible product for their specific needs.

The Importance of Foam Conversion in Modern Applications

Foam conversion is crucial in many industries, providing tailored solutions that address diverse challenges. Whether for comfort, protection, or insulation, the versatility of foam makes it a valuable material in numerous sectors. The continuous evolution of foam conversion technologies also promises exciting developments in product design and functionality.

Collaboration for Effective Solutions

At Acoustafoam, collaboration with clients is key to achieving optimal results. By understanding the specific challenges faced by various industries, Acoustafoam can provide effective solutions that go beyond simple foam products. Whether it involves acoustic insulation in construction vehicles or thermal insulation in yacht engine rooms, our team is dedicated to helping clients overcome obstacles through innovative foam conversion techniques.

Benefits of Foam Conversion

The benefits of foam conversion extend beyond the production of basic foam products. Here are some key advantages:

- Versatility: Foam can be adapted for various applications, making it suitable for numerous industries.

- Customization: Tailored solutions ensure that products meet specific requirements for size, shape, and functionality.

- Cost-Effectiveness: Foam conversion processes can lead to significant savings by optimizing materials and reducing waste.

- Environmental Sustainability: The use of eco-friendly materials in foam conversion helps reduce environmental impact.

- Quality Assurance: Strict quality control measures guarantee that the final products meet industry standards.

Read Also: Plumbers Near Me in Hitchin: Why Hiring Local Experts Matters

Conclusion: The Future of Foam Conversion

Foam conversion is an essential process that transforms versatile foam materials into specialized products for diverse applications. With advancements in technology and an increasing focus on sustainability, the future of foam conversion looks promising. As industries continue to evolve, so too will the methods and applications of foam conversion, ensuring that this valuable material remains integral to countless sectors.

For more information about foam conversion products and how they can benefit your business, don’t hesitate to contact Acoustafoam. We look forward to helping you find the right solutions for all your foam conversion needs.